Our Manufacturing Process

From raw material selection to final packaging, every step in our factory follows strict quality standards to ensure consistency, safety, and reliability for furniture importers worldwide.

Complete Manufacturing Workflow

Our standardized 8-step process ensures consistent quality and precision from raw materials to finished furniture products ready for global export.

Raw Material Selection

Premium grade MDF, particle board, and plywood sourced from certified suppliers with strict moisture content control.

CNC Machining

Precision cutting and drilling with ±1mm accuracy using advanced multi-axis CNC equipment for perfect component dimensions.

Component Shaping

Edge banding, profiling, and surface preparation to achieve smooth finishes and precise tolerances for assembly.

Assembly

Professional joinery using cam locks, dowels, and hardware components ensuring structural integrity and durability.

Surface Treatment

Application of melamine, PVC film, veneer, or paint finish with consistent color matching and texture quality.

Curing Process

Controlled temperature and humidity curing chambers to ensure optimal adhesion and finish durability.

Quality Control

Multi-point inspection including dimensional accuracy, finish quality, and structural integrity testing per international standards.

Packaging

Custom protective packaging with drop-test certification, optimized for container loading and international shipping.

Our Commitment to Your Success

Every step in our manufacturing process is designed with your business needs in mind. From ensuring consistent quality for your customers to meeting international compliance standards for smooth customs clearance, we handle the details so you can focus on growing your furniture business.

Premium Material Selection & Climate-Controlled Storage

Your customers expect consistent quality, which starts with the right materials. We source only certified MDF, particle board, and plywood from approved suppliers, ensuring every piece meets your market's safety and environmental standards.

- Pre-delivery testing for formaldehyde emission levels (E1/E0, CARB Phase 2 compliance)

- Moisture content verification to prevent warping and dimensional changes

- Climate-controlled warehouse storage maintaining optimal temperature and humidity

- Batch tracking system for complete traceability and quality accountability

Precision Cutting & Advanced CNC Machining

Inconsistent dimensions mean assembly problems for your customers. Our precision cutting and CNC machining ensure every component fits perfectly, reducing returns and customer complaints while building trust in your brand.

- ±0.5-1mm precision tolerance using advanced electronic saws and CNC equipment

- Automated drilling, slotting, and chamfering for perfect component preparation

- Quality control checks at each cutting stage to maintain dimensional accuracy

- Optimized cutting patterns to minimize waste and reduce your product costs

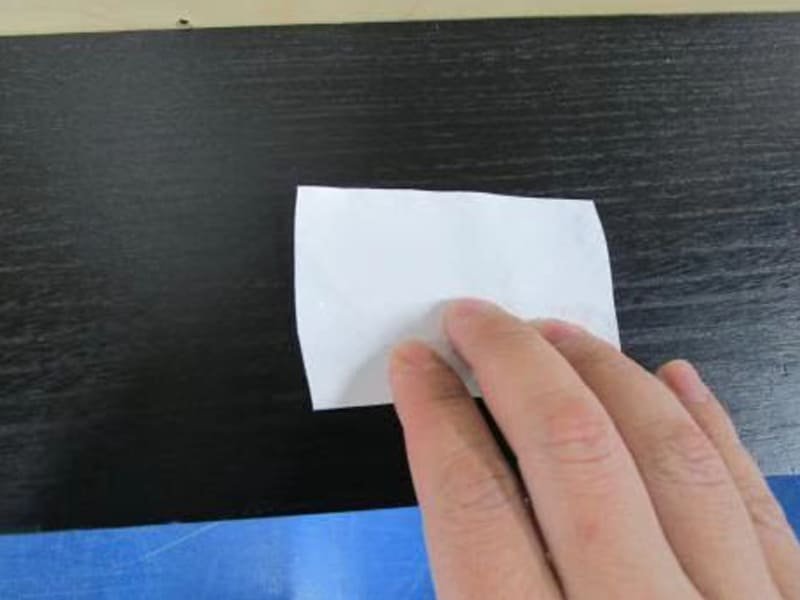

Professional Edge Banding & Surface Finishing

Exposed edges can absorb moisture and fail over time, leading to warranty claims. Our comprehensive edge sealing and surface finishing process protects every panel, ensuring your furniture maintains its appearance and structural integrity throughout its lifecycle.

- Four-edge sealing using advanced edge banding machines to prevent moisture absorption

- Automated sanding combined with skilled hand finishing for smooth, consistent surfaces

- Safety chamfering and edge profiling to eliminate sharp corners and enhance aesthetics

- Surface inspection ensuring uniform texture and preparing for optimal finish adhesion

Structural Assembly & Hardware Integration

Your customers want furniture that's easy to assemble but built to last. We use proven connection systems and reinforce critical joints with quality hardware, giving you confident assembly experiences and long-term customer satisfaction.

- Three-in-one connector systems and precision dowels for secure, repeatable assembly

- Strategic metal hardware reinforcement at high-stress connection points

- Assembly-friendly design ensuring DIY customers can achieve professional results

- Load-bearing optimization to exceed typical household furniture usage requirements

Advanced Surface Treatment & Color Matching

Consistent color and finish quality across every piece is crucial for your brand reputation. Our multi-option surface treatment capabilities and precise color matching ensure your furniture collections maintain visual harmony and meet your customers' expectations.

- Multiple finish options: melamine lamination, PVC film, wood veneer, and UV spray coating

- Automated application systems ensuring uniform coverage and consistent quality

- Color matching technology maintaining consistency across large production runs

- Durability testing for scratch resistance, moisture protection, and UV stability

Controlled Curing & Quality Stabilization

Properly cured finishes resist wear, maintain color, and provide long-lasting protection. Our controlled curing process ensures your furniture arrives ready for immediate use and maintains its appearance throughout years of customer use.

- Temperature-controlled curing chambers optimizing finish adhesion and hardness

- UV curing and infrared drying technology accelerating process without compromising quality

- Multi-stage curing ensuring complete polymerization and maximum durability

- Post-cure quality verification confirming finish integrity before proceeding to final steps

Comprehensive Quality Control & Compliance Testing

Meeting international standards isn't just about passing customs—it's about protecting your business reputation and ensuring customer safety. Our rigorous testing protocols verify every aspect of quality and compliance before your furniture ships.

- Dimensional accuracy verification ensuring perfect component fit and assembly success

- Surface quality inspection checking for consistency, smoothness, and color matching

- Structural integrity testing including load-bearing and stability assessments

- International compliance testing: EN, ASTM, E1/E0, CARB Phase 2 standards verification

Export-Optimized Packaging & Shipping Protection

Damaged goods mean lost profits and unhappy customers. Our export-grade packaging protects your investment during international shipping while maximizing container efficiency to keep your landed costs competitive.

- Flat-pack design with comprehensive protection: foam padding, corner guards, and reinforcement boards

- Drop and vibration testing meeting Amazon and Wayfair e-commerce packaging standards

- Container loading optimization maximizing volume efficiency and reducing shipping costs

- Damage rate below 0.5% ensuring your furniture arrives in perfect condition for customers

International Standards & Certifications

Your business success depends on reliable suppliers who meet international standards. Our comprehensive certifications ensure smooth customs clearance, customer safety, and marketplace acceptance.

ISO 9001 Certified

International quality management system certification ensuring consistent production standards and continuous improvement processes.

FSC Sustainable Wood

Forest Stewardship Council certified materials ensuring responsible forest management and environmental sustainability.

EN/ASTM/E1 Standards

Full compliance with European EN standards, American ASTM specifications, and E1/E0 formaldehyde emission requirements.

Amazon/Wayfair Approved

Packaging passes rigorous drop and vibration testing standards required by major e-commerce platforms for damage-free delivery.

Ready to Work with a Certified Partner?

Our certifications eliminate compliance risks and ensure your furniture orders meet all international standards. Get a detailed quote with full documentation support.